Availability: In Stock

Ex Tax: $157.00

Main imfomation:

|

Model

No: |

Price |

Material |

Appearance |

Standard |

|

GP3-15C3/C4 |

$157 |

Aluminum Alloy |

Customizable |

National |

|

GP3-20C3/C4 |

$199 |

Aluminum Alloy |

Customizable |

National |

|

GP3-30C3/C4 |

$245 |

Aluminum Alloy |

Customizable |

National |

|

GP3-40C3/C4 |

$439 |

Cast Iron |

Customizable |

National |

|

GP3-50C3/C4 |

$565 |

Cast Iron |

Customizable |

National |

|

GP3-60C3/C4 |

$657 |

Cast Iron |

Customizable |

National |

Product description:

This Rolling ring linear drive is non-positive drives which convert the rotation of a plain shaft into linear motion. In contrast to rolling ring drives, the rolling rings are not arranged to swivel but are fitted at a fixed angel of pitch, the speed being varied by varying the speed of the shaft. The change of direction is achieved by reversing the direction of rotation of the shaft.

We only sell high-quality rolling ring drive units. The following three series are for you to choose from:

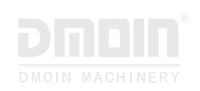

A Series :Rolling ring drive unit type A series just have one Rolling Ring linear drive , which are divided into eight types according to the diameter of the shafts.

B Series: Rolling ring drive unit type B series just have one Rolling Ring linear drive with guide rollers or guide wheel , which are divided into six types according to the diameter of the shafts.

C series : Rolling ring drive unit type C series just have One Rolling Ring linear drive with accessories, such as shaft, guide roller, bearing block, steady bar,etc , which are divided into eight types according to the diameter of the shafts.

Application areas:

It is mostly used in industry. Used in textile machine, spooling machine, inspection technology, wire winding machine, engine controls, linear drive system, medical equipment, etc.

Purchase Notes:

For orders of more than 2 units, you can contact us for more discounts.

Please contact us for the latest shipping information before placing an order.

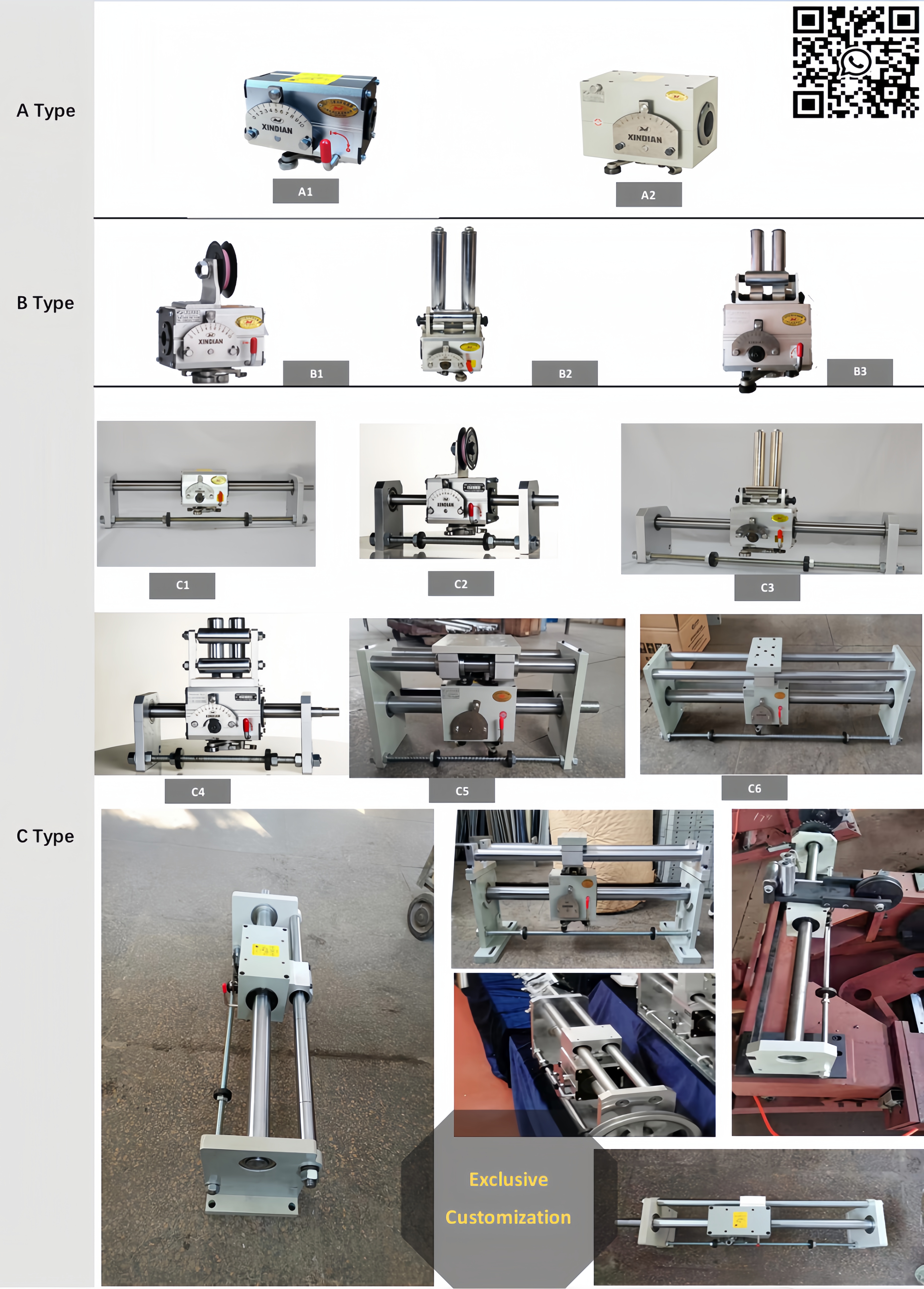

Installation dimension:

Product instructions:

- Installation accessories

There are four holes in the top of the Rolling Ring Drive which are used to fix the accessories. The bolts shall not be over screwed so that the apparatus works well. For the deepness of threaded holes see the Dimension Table of Installation.

- Pitch adjustment

The range 0-10 on the pitch selection scale is used to adjust the traverse pitch, by pressing down the indicator to separate the positioning tooth from the scale and then move it to adjust.

- Free-Movement lever

The Free-Movement Lever must be in loose state when setting up the Polished Shaft. If the Free-Movement Lever is at O position (horizontal position), the Rolling Ring Drive can be moved freely to locate the start point of wire rolling ring.

- Rotation direction of the polished shaft adjustment

The rotation direction of the Polished Shaft is related to the position of Reversal Wheel. The down-ward rotating of the shaft is defined positive direction in the face of Pitch Selection Scale. When the shaft is required to be reversal, please reinstall and adjust the position of reversal wheel by 180°.

- Thrust adjustment

There are two pressure adjusting nuts on the rolling ring drive, one is at the top center and the other is at the bottom right. A slight turning will adjust the thrust force. The nuts have been well-adjusted, so please do not turn them. If the thrust cannot reach the requirement of wire rolling ring adjust the two nuts to get the appropriate one.

- Maintenance

The rolling ring drive is a precise apparatus which has been well-adjusted when it leaves the factory. Disassembly is not allowed. No.20 machine oil should be regularly serviced on the shaft when be in use to keep the work surface oiled. The Free-Movement Lever should be at 0 position when be not in use.

- Pitch error adjustment

When the left traverse pitch is not the same as the right one, loosen the screw and adjust the eccentric nut to reach the required result. Then fasten the screw.